| Machine Model | GNL-5545H(Sealer) | GNS-5030LW + L(Shrink Tunnel) |

| Packaging /Cavity Size | L(no limit) W+H<450mm H<150mm | L1800 X W500 X H300mm |

| Packaging Speed | 0-60 bpm | |

| Height of Table | 820mm±50mm | |

| Suitable Film | POF/BOPP heat shrink film | |

| Sealing knife Size | 3Ф220V/380V 50Hz | |

| Power Supply | ≤500mm | / |

| Power | 3.5KW | 13KW |

| Air Pressure | 6kg/cm3 | / |

| Net Weight | 550kg | 350kg |

| Machine Dimension | L2100 X W1500 X H1300mm | L2000 X W990 X H1300mm |

| No. | Name | Brand |

| 1 | PLC | OMRON, JAPAN |

| 2 | Knife Servo Motor | MITSUBISHI |

| 3 | Sealing Knife | Dupont(US) |

| 4 | Brake Motor | TAIBANG(TAIWAN, CHINA) |

| 5 | Touch Screen | MCGS |

| 6 | Circuit Breaker | SCHNEIDER, FRANCE |

| 7 | Temperature Controller | OMRON, JAPAN |

| 8 | Ac Contactor | SCHNEIDER,FRANCE |

| 9 | Material Induction Switch | BONNER, USA |

| 10 | Solid-state Relay | OMRON, JAPAN |

| 11 | Air Cylinder | SHAKO(TAIWAN, CHINA) |

| 12 | Cylinder Solenoid Valve | SHAKO(TAIWAN, CHINA) |

| 13 | Air Filter | SHAKO( TAIWAN, CHINA ) |

| 14 | Proximity Switch | SICK, GERMAN |

| 15 | Conveyor Belt | SIGLIN, GERMEN |

| 16 | Power Switch | TIANYI, CHINA |

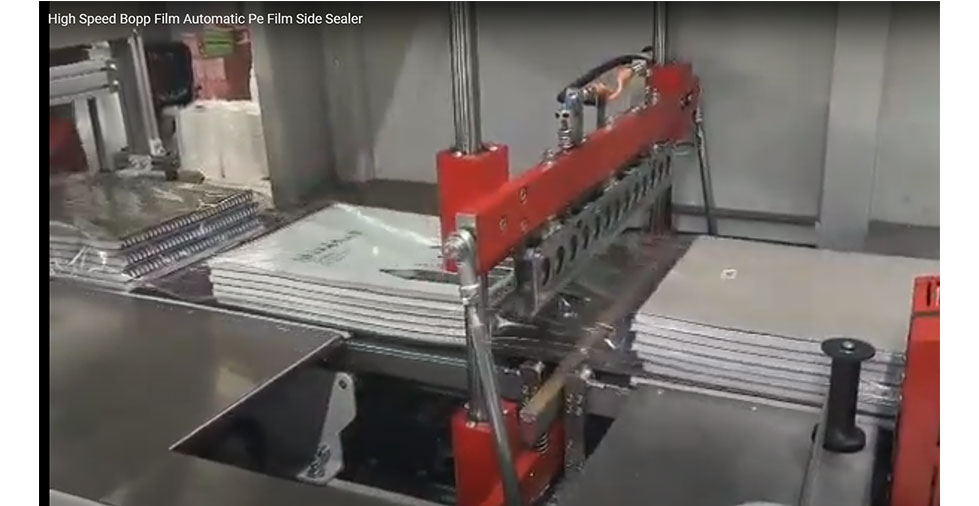

The servo motor can operate smoothly and reliably without displacement during the process of high-speed transmission.

Equipped with an adaptive feed system, the feed speed is automatically adjusted according to the speed of the host auto packing machine.

The color touch operation interface completes the modification of all action parameters, data storage, call and fault display. By simply calling the stored program, the operator can quickly call the required data on the data storage page. The automatic error detection function is displayed on the screen, which makes it easier for the operator to make corrections.

Servo motor control of overall performance, including feeding, film dragging, sealing, shrinkage and discharging, to make it run smoothly at high speed.

Equipped with appropriate feeding system to realize full-automatic packaging for different production lines of products and save labor cost.

Adopts pre-blowing at the bottom of the tunnel to make full use of the energy efficiency generated by heat energy. Inverter controls blowing. Blowing direction and volume can be adjusted from the bottom.

The visual window of our automatic side sealing machine shows the process of film contraction inside the tunnel.

The top of the tunnel can be opened for easy cleaning and maintenance.

The conveying speed can be adjusted to control the equal distance between products to ensure consistent sealing.

Suitable for large product packaging, such as CD, photo frame, books, magazines, electronic products, etc.